|

|

|

|

| |

|

|

|

| Subject |

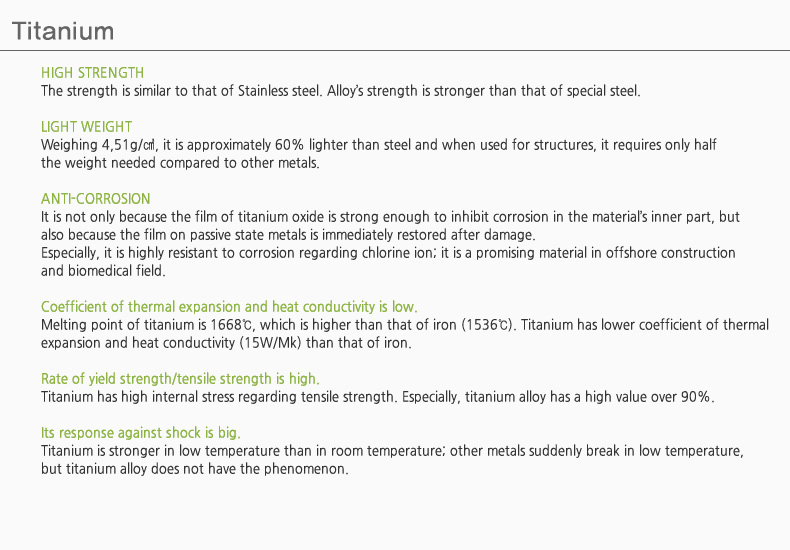

TITANIUM |

|

| Name |

Admin

|

|

| Date |

Hit : 2682, Date : 2016/04/01 21:48 |

|

|

|

|

| |

|

|

|

| |

|

▣ Types of Titanium

| |

Grade |

Feature |

Main Use |

Pure

Titanium |

Grade 1 |

Low strength |

Plate-type heat exchanger |

| Grade 2 |

Optimal combination of most-used Pure Titanium |

pipe’s |

| strength and weldability |

| Grade 3 |

High strength |

Tube-type heat exchanger,

Pressure-resistant skin |

Titanium

Alloy |

Grade 5 |

The most produced Titanium Alloy |

aircraft, submarine |

| high strength, high heat-resistance |

| Grade 7 |

High corrosion-resistance |

chemistry |

| Grade 9 |

High strength + high corrosion-resistance |

submarine,

water pressure pipes |

| Grade 11 |

Similar to Grade 7 |

submarine exploration |

| Grade 12 |

High temperature resistance than Pure Titanium |

tube-type heat exchanger,

pressure-resistant skin |

| |

| |

|

|

|

| |

|

▣ Titanium’s Standard

Stan

dards |

Grade |

chemical substances(MAX, %) |

Mechanical Property (annealing) |

| N |

C |

H |

Fe |

O |

Ti |

tensile strength |

proof stress(0.2%offset) |

elongation(%) |

| kgf/mm |

Ksi |

Mpa(N/mm) |

kgf/mm |

Ksi |

Mpa(N/mm) |

| ASTM |

Grade 1 |

0.03 |

0.10 |

0.015 |

0.20 |

0.20 |

rema

ining |

>=25 |

>=25 |

>=240 |

18~32 |

24~45 |

170~310 |

>=24 |

| Grade 2 |

0.03 |

0.10 |

0.015 |

0.30 |

0.30 |

>=35 |

>=50 |

>=345 |

24~46 |

40~65 |

275~450 |

>=20 |

| Grade 3 |

0.05 |

0.10 |

0.015 |

0.30 |

0.30 |

>=46 |

>=65 |

>=450 |

39~56 |

55~80 |

380~550 |

>=18 |

| Grade 4 |

0.05 |

0.10 |

0.015 |

0.50 |

0.50 |

>=56 |

>=80 |

>=550 |

49~67 |

70~95 |

485~655 |

>=15 |

| |

| |

|

|

|

| |

|

▣ Titanium Alloy’s Standard

Stan

dard |

Grade |

chemical substances(MAX, %) |

Mechanical Property

(annealing) |

| N |

C |

H |

Fe |

O |

Ai |

V |

Pd |

Ti |

tensile

strength |

proof

stress

(0.2% offset) |

elongation

(%) |

Mpa

(N/m) |

Mpa

(N/m) |

| ASTM |

Grade5 |

0.05 |

0.10 |

0.015 |

0.40 |

0.20 |

5.5~

6.75 |

3.5~4.5 |

- |

rema

ining |

895 |

830 |

10 |

| Grade7 |

<=0.03 |

<=0.10 |

<=0.015 |

<=0.30 |

<=0.25 |

- |

- |

0.1~

0.25 |

>=345 |

275~450 |

>=20 |

Grade

11 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| |

| |

|

|

|

| |

|

▣ Comparative Table of Titanium Corrosion Resistance

| |

Titanium |

Titanium

alloy |

Aluminum |

Aluminum

alloy

7075-T6 |

Iron |

18-8 STAINLESS AISI304 |

Hastelloy C |

| melting point |

1,668 |

1,540~1,650 |

660 |

476~638 |

1,530 |

1,400~1,427 |

1,305 |

| density(g/㎤) |

4.51 |

4.42 |

2.70 |

2.80 |

7.86 |

8.03 |

8.92 |

| Atomic Number |

22 |

22 |

13 |

13 |

26 |

26 |

- |

| Atomic Weight |

47.90 |

- |

26.97 |

- |

55.85 |

- |

- |

Young's modulus

(㎬) |

108.5 |

1115.5 |

70.5 |

72.8 |

196.0 |

203.2 |

208.6 |

| Poisson`s ratio |

0.34 |

0.30~0.33 |

0.33 |

0.33 |

0.31 |

0.29 |

- |

Resistivity

(μΩ-㎝,20℃) |

47~55 |

171 |

2.7 |

5.8 |

9.7 |

72 |

130 |

Electric

conductivity

(Compared to

that of Cu,%) |

3.1 |

1.1 |

64.0 |

30.0 |

18.0 |

2.4 |

1.3 |

Thermal

conductivity

(cal/㎤/sec/℃/㎝) |

0.041 |

0.018 |

0.487 |

0.294 |

0.145 |

0.039 |

0.031 |

Coefficient of linear

expansion

( ㎝/㎝/℃, 0~100℃) |

8.4×10-6 |

8.8×10-6 |

23.0×10-6 |

23.1×10-6 |

12.0×10-6 |

16.5×10-6 |

11.5×10-6 |

Specific heat

(cal/g/℃) |

0.12 |

0.13 |

0.21 |

0.23 |

0.11 |

0.12 |

0.09 |

| |

| |

|

|

|

| |

|

▣ Comparative Table of Titanium Corrosion Resistance Feature

| |

Corrosion medium |

Composition

(%) |

Temperature

(℃) |

Corrosion Resistance |

|

Pure

Titanium |

Zirconium |

SUS304 |

SUS316 |

Hastelloy |

Inorganic

acids |

Hydrochloric Acid

(HCl) |

1 |

25 |

A |

A |

B |

A |

A |

| |

boiling |

D |

A |

D |

D |

C |

| 10 |

25 |

B |

A |

D |

D |

C |

| |

boiling |

D |

A |

D |

D |

D |

Sulphuric Acid

(H2SO4) |

10 |

25 |

A |

A |

A |

A |

A |

| |

boiling |

D |

A |

D |

C |

B |

| 10 |

25 |

B |

A |

B |

B |

A |

| |

boiling |

D |

A |

D |

D |

B |

Nitric Acid

(HNO3) |

10 |

25 |

A |

A |

A |

A |

A |

| |

boiling |

A |

A |

A |

A |

B |

| 65 |

25 |

A |

A |

A |

A |

B |

| |

boiling |

A |

A |

B |

B |

D |

Organic

acid |

Acetic Acid

(CH3COOH) |

10 |

boiling |

A |

A |

A |

A |

A |

| 60 |

boiling |

A |

A |

B |

B |

A |

Oxalic Acid

((COOH)2) |

10 |

25 |

A |

A |

C |

B |

A |

| 30 |

boiling |

D |

A |

D |

D |

A |

Sacrolactic Acid

(CHO3CH(OH)COOH) |

10 |

25 |

A |

A |

B |

B |

B |

| 85 |

boiling |

A |

A |

D |

D |

B |

| Alkali |

Caustic Soda

(NaOH) |

10 |

100 |

A |

A |

A |

A |

A |

| 40 |

boiling |

D |

B |

B |

B |

B |

Potassium Carbonate

(K2CO3) |

5 |

boiling |

A |

A |

A |

A |

A |

| 20 |

boiling |

A |

A |

A |

A |

A |

Inorganic

chlorides |

Sodium Chloride |

25 |

25 |

A+ |

A |

B+ |

B+ |

B |

| - |

boiling |

A |

B |

B+ |

B+ |

B+ |

Magnesium

Chloride |

42 |

25 |

A+ |

A |

A+ |

A+ |

A |

| |

boiling |

A |

A |

A+ |

A+ |

A+ |

| Ferric Chloride |

30 |

25 |

A+ |

D |

D |

D |

C |

| - |

boiling |

A |

D |

D |

D |

D |

Inorganic

salts |

Sodium

Sulfate |

25 |

25 |

A |

A |

A |

A |

A |

| - |

boiling |

A |

A |

A |

A |

A |

Sodium

Nitrate |

10 |

25 |

A |

A |

A |

A |

A |

| - |

boiling |

A |

A |

B |

B |

A |

Sodium

Carbonate |

30 |

25 |

A |

A |

A |

A |

A |

| - |

boiling |

A |

A |

A |

A |

A |

| Gas |

Chlorine |

Dryness |

25 |

D |

A |

A |

A |

A |

| Dampness |

25 |

A+ |

D |

D |

D |

D |

Hydrogen

Sulfide |

Dryness |

25 |

A |

A |

C |

B |

A |

| Dampness |

25 |

A |

A |

B |

A |

B |

| Ammonia |

100 |

40 |

A |

A |

A |

A |

A |

| - |

100 |

A |

A |

A |

A |

A |

| Etc. |

Seawater |

- |

25 |

A |

A |

A+ |

A+ |

A |

| - |

100 |

A+ |

A |

B+ |

B+ |

A+ |

| Naptha |

- |

80 |

A |

A |

A+ |

A+ |

A |

| - |

180 |

A |

A |

A+ |

A+ |

A |

A : 0.125mm/year or less B : 0.125~0.5mm/year C : 0.5~1.25mm/year D : 1.25mm/year

※ Sometimes provokes local corrosion including pitting corrosion and corrosion of crack |

| |

| |

|

|

| |

|

|

|

|

CopyRight Since 2001-2026 WEBARTY.COM All Rights RESERVED. / Skin By Webarty |

|

|

|

| |

HANSUNG M TECH CO., LTD. |

| |

97, Hwanggeum-ro 128beon-gil, Yangchon-eup, Gimpo-si, Gyeonggi-do, Korea (2742, Hagun-ri)

TEL : 82-32-684-1667 FAX : 82-31-998-1670 E-MAIL : hsic@hsic.co.kr

Copyright ⓒ 2016 HANSUNG M TECH CO., LTD. All Rights Reserved. |

|